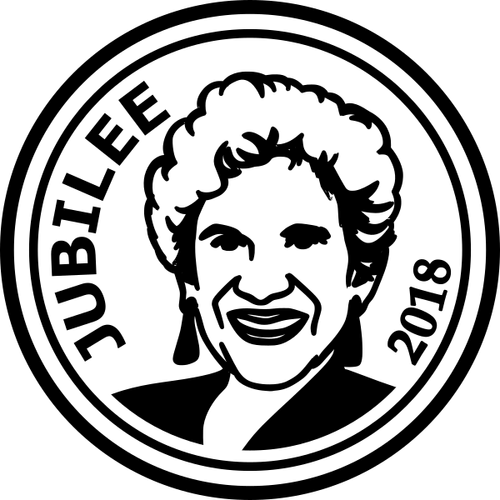

Chocolate Medal

A commemorative chocolate medal created as a party favor for my wife's grandmother's 90th birthday.

With an expanding arsenal of tools, I'm driven to tackle increasingly complex and interesting challenges. This project encompasses graphic design, CAD/CAM, CNC engraving, vacuum forming, and confectionery.

I began by commissioning a talented Fiverr artist (ruxandradraws) to convert a photograph into a vector line drawing. After receiving the drawing, I arranged the graphic into the final coin shape.

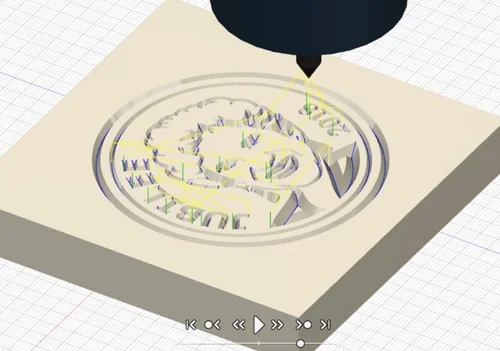

Next, I set up the engraving in Fusion 360 CAM and machined it with a v-bit on extruded plexiglass. I drilled tiny holes in every depression to allow air to escape during vacuum forming. Using a dental vacuum former, I created five flexible molds for casting the chocolate medals from the plexiglass buck.

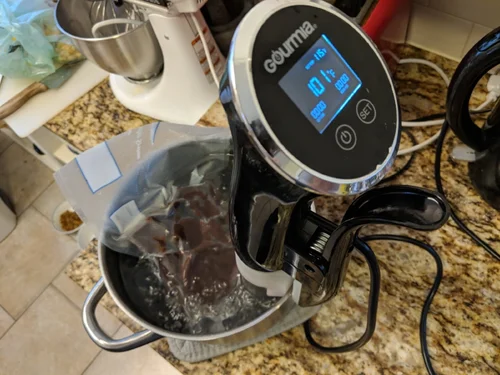

The most challenging aspect of the project was tempering the chocolate. Despite several attempts with traditional methods and the sous vide technique recommended by Serious Eats, I only achieved successful pours half of the time. Eventually, I produced enough medals for everyone at the party, but I have yet to master chocolate making.